3V2M solenoid valve

2021-06-29 900

Product features:

1. Direct acting structure, sensitive to directional changes;

2. Normally closed and normally open options are available;

3. Coaxial cut-off structure, good sealing performance, and large flow rate;

4. No need for oil lubrication;

5. Equipped with a manual device for easy installation and debugging;

6. The valve body can be used in conjunction with the base, allowing for the integration of multiple valves and saving space;

7. Unified air intake and wiring, making it easy to find faults;

8. Flexible combination and strong expandability, the number and type of solenoid valves connected can be freely combined or expanded;

9. Special base sealing gasket, flipping the sealing gasket can achieve normally closed and normally open conversion.

Product specifications:

Installation and use:

1. Before use, pay attention to checking whether the components are damaged during transportation, and then install and use them;

2. Please pay attention to the correct direction of gas flow and the shape of the connecting pipe during installation. The use of media must go through 40 μ M filter element filtration;

3. Please pay attention to whether the installation conditions meet the technical requirements (such as "voltage", "operating frequency", "working pressure", "operating temperature range", etc.) before installation and use;

4. Pay attention to the direction of gas flow during installation, where P is the inlet, A (B) is the working port, and R (S) is the exhaust port;

5. Try to avoid using in environments with vibrations and pay attention to anti freezing measures at low temperatures;

6. When connecting pipelines, be careful not to wrap the sealing tape beyond the end face of the joint teeth. Pay attention to removing dust, iron filings, and other dirt from the pipeline joints to prevent impurities or foreign objects from entering the valve body;

7. Please pay attention to dust prevention. It is recommended to install a muffler or noise reduction throttle valve at the exhaust port. When not in use, dust covers should be installed at the inlet and outlet ports.

8. When debugging the entire machine, it is recommended to first use a manual device for debugging, and then power on for debugging.

Order code:

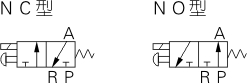

Functional symbols:

-

05-16

Jiangmen hydraulic component manufacturer: displacement of hydraulic pump

It is estimated that many people are not very clear about the displacement and flow rate of hydraulic pumps. Benzhengyun Hydraulic Editor will analyze the displacement and flow rate of hydraulic pumps

-

04-06

Jiangmen Hydraulic Component Manufacturer: What are the specific characteristics of hydraulic filter cartridges

Hydraulic filter element is used to purify and treat unqualified turbine oil, especially those with excessive acidic substances in the oil. So what are its detailed features?Features:1. Use three-leve